The Sidwell Friends Robotics Team has been preparing rigorously for the upcoming CENTERSTAGE competition, where the robots they have been designing will be put to the test in a series of challenges.

The CENTERSTAGE competition includes a variety of tasks to test the design and durability of the robots. The main challenge involves using robots to place game pieces, called pixels, against an angled backboard for points. This “game” takes place on a 12 foot by 12 foot foam-bottom playing field, where each team is assigned to play against another partnership to advance. According to junior and returning member of the Robotics Team Deanna Paukstitus, most teams are eliminated within the first few hours, and only two teams advance beyond the qualifiers.

The process of preparing for this competition has been difficult, with members facing new challenges that require innovative solutions. One of the tasks in CENTERSTAGE is to have the robot suspend itself from the game structure, which requires a careful design that accounts for the many challenges involved in this task.

In another challenge, the robot could earn points by firing a paper airplane into three different end zones outside of the playing field, earning either 10, 20 or 30 points. Not only does this call for scrupulous programming to ensure the robot throws the airplane correctly, but it also requires an understanding of aerodynamics.

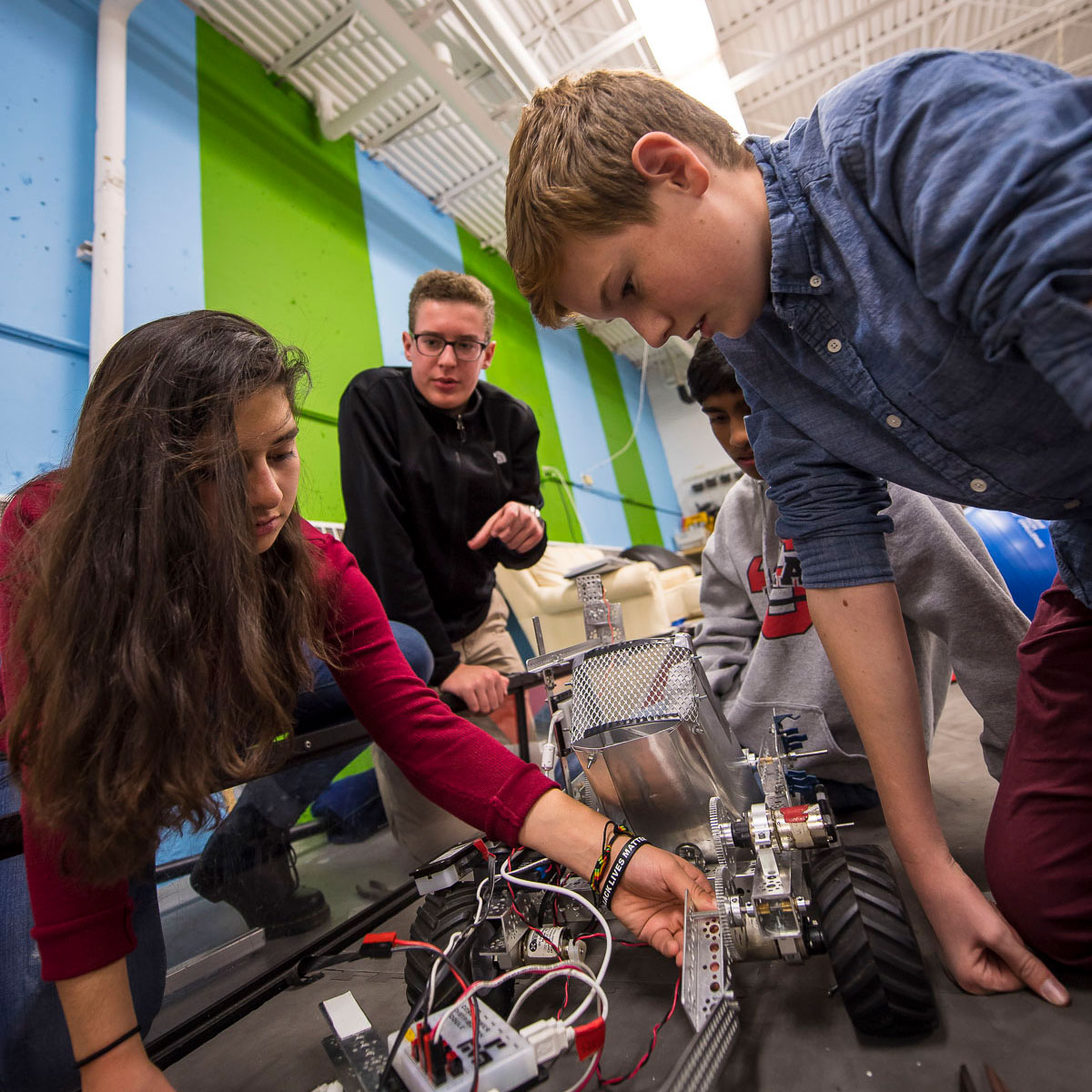

In terms of building the robot itself, Paukstitus explained, “We build our robots with a combination of 3D-printed parts and traditional robotics components purchased online or made ourselves. Metal extrusions, chains, belts, gears, wheels… you name it, we probably use it.”

She also mentioned that the team is only allowed to use DC motors — which is a motor that turns energy from a direct current and turns this into mechanical energy — and servos, which are electronic devices and rotary or linear actuators that rotate and push parts of a machine with precision. All other alternatives are banned which makes cracking these challenges more difficult.

The programming behind these robots is just as complex as the engineering that built them. The robots are programmed using Java, but the teams must utilize other resources such as color sensors to “make [the] robots more dynamic, create autonomous routines, and more,” Paukstitus said.

As the team has worked to prepare for the competition, they have also established a work dynamic that is inclusive and allows members to work and learn well together. Paukstitus describes the team environment as “very, very welcoming. None of us are professionals when we enter, but everyone learns something by the time they leave. When you join, it is virtually impossible to be left out or bored.”

The team also works to make sure new members can learn robotics at their own pace. New members spend the season on a team exclusively for them, which gives each recruit the chance to learn individually without being spoken over by those with more experience.

The positive dynamic of the team has made robotics a closely knit community. Paukstitus concluded, “We are very accepting of diverse ideas, appreciate our team’s company, and lift each other up. You form a close bond with the people you work with, so you will inevitably begin to make friends. Robotics is a great place to learn and test yourself while also meeting new people and building valuable teamwork skills.”